Original Xhorse Condor XC-002 Mechanical Key Cutting Machine with 3 Years Warranty DHL Free

Item No. SL355

Out of Stock.

History 226 sold.

Buy Now: £1,008

4% Automatic Discount Except Specials

UK/UE Ship

Contact us to get better price

Email: Sales01@Xhorse.co.uk

WhatsApp: +86 17308368390

UK/UE Ship

Contact us to get better price

Email: Sales01@Xhorse.co.uk

WhatsApp: +86 17308368390

Weight:

28.0KG

( 61.73LB )

Package:

59.5cm*55cm*37.5cm

( Inch: 23.43*21.65*14.76 )

Returns:

Return for refund within 7 days,buyer pays return shipping. Read details »

Related Download Files

Product Description

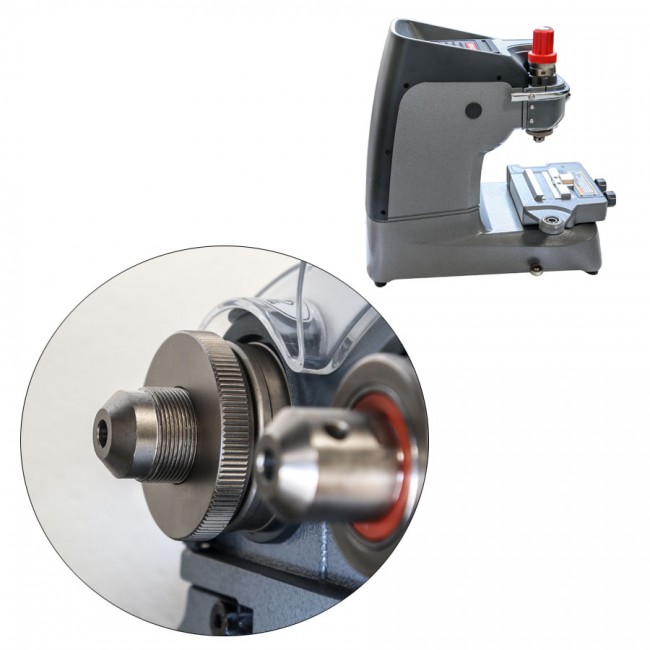

Xhorse Condor XC-002 Manually Key Cutting Machine with 3 Years Warranty is a professional device. It enables locksmiths to copy and process keys more efficiently and accurately for vehicles or civil use.

Xhorse Condor XC-002 Manually Key Cutting Machine

Xhorse Condor XC-002 Highlights:

1. Ergonomic design provides the better user experience

2. Aluminum-casting body make it more reliable and durable

3. The adjustable high-speed motor ensures the stability and fluency of operation.

4. Built-in indicator lights make the height level adjustment easier

5. Cross rail guarantees the accuracy

6. Supporting track and dimple cutting, that can process special keys

7. More key types are available because of the 4-side rotary clamp

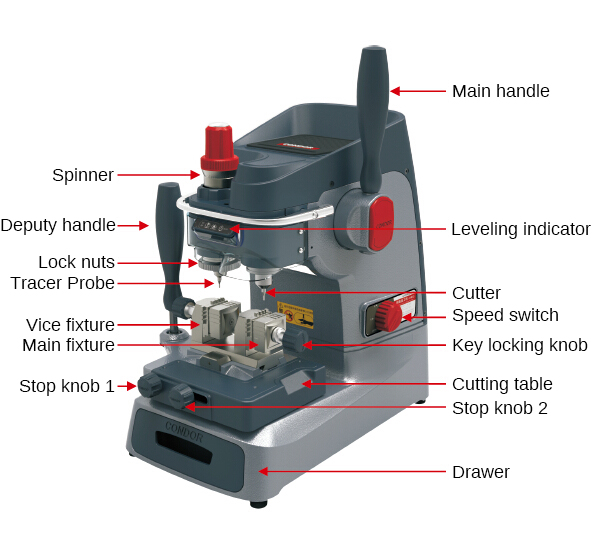

Xhorse Condor XC-002 Overview:

Xhorse Condor XC-002 Specifications:

Condor XC-002 Machine Installation:

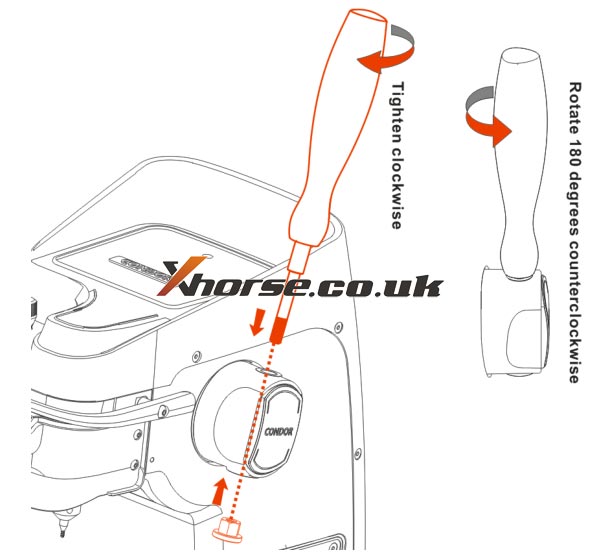

1. Installing Main Handle

1) Insert the bottom of the main handle into the installing hole, which is by the right side of the machine body. Then cover the screw cap and rotate the handle clockwise until tightened.

2) If fully tightened, the main handle should be fixed at a certain position and unable to move up or down.

3) If rotate the handle 180 degrees counterclockwise, the height of the tracer and cutter can be changed freely.

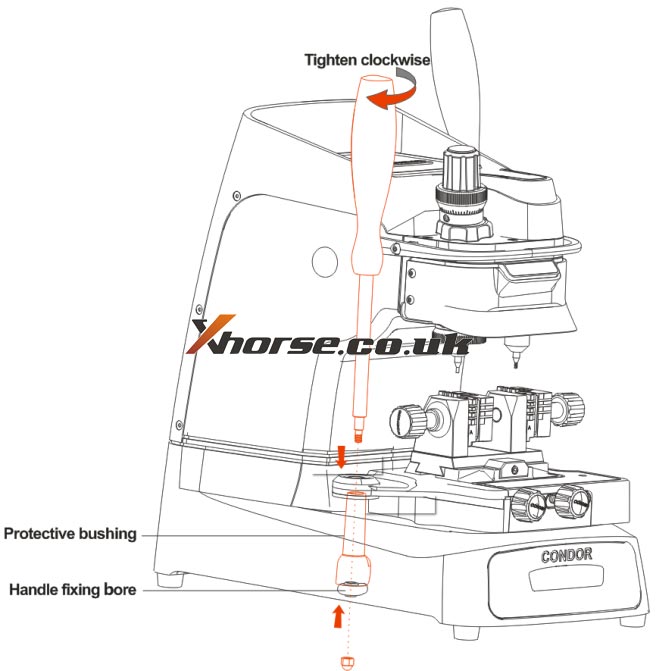

2. Installing Sub-Handle

Insert the bottom of the sub-handle into the installing hole, which is by the left side of the machine body. Put on the protective bushing and then plug in the lower bearing bore to avoid moving. Cover the screw cap and rotate the handle clockwise until tightened.

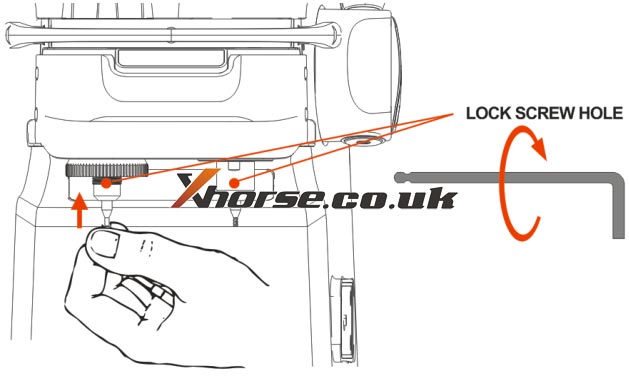

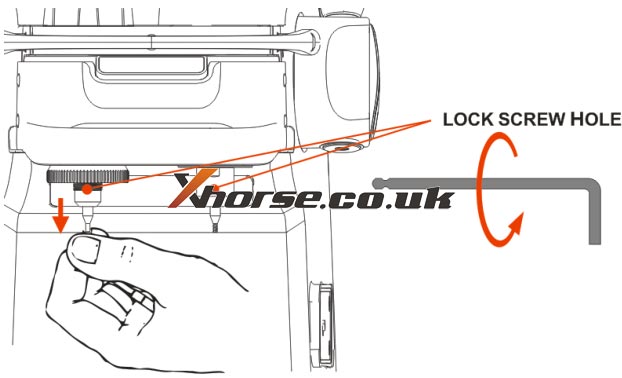

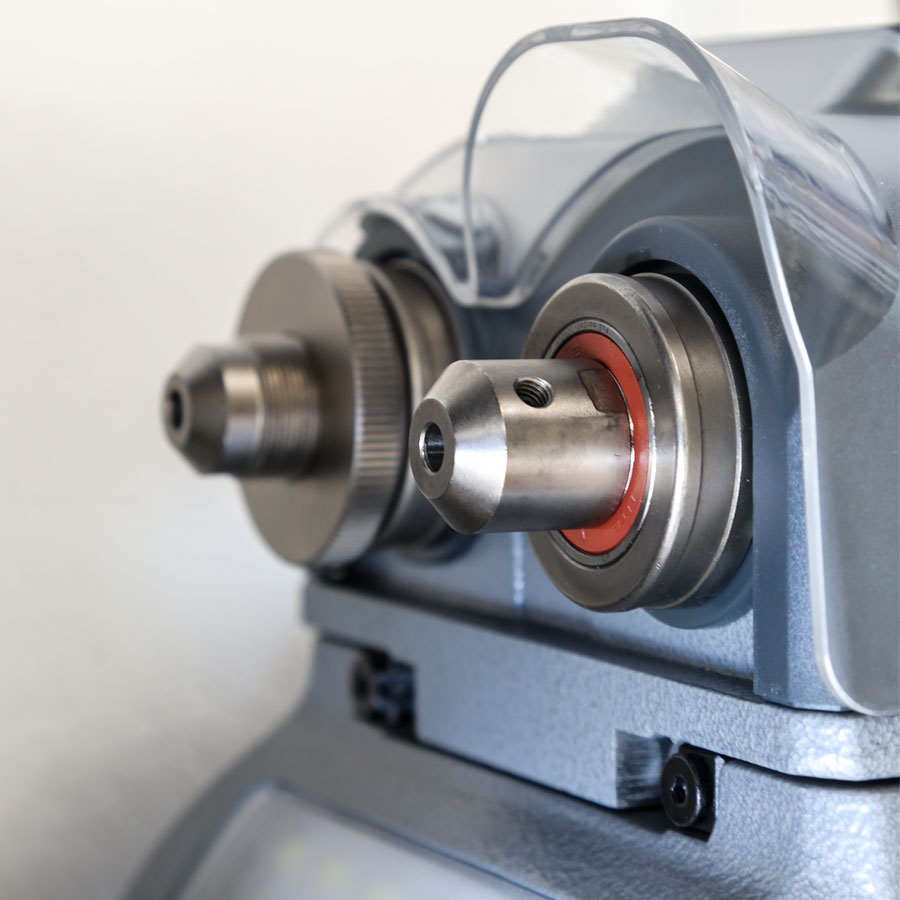

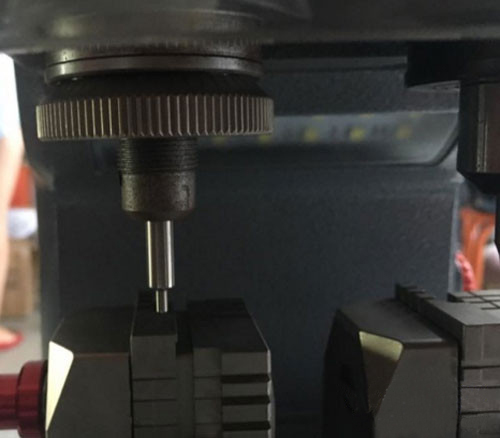

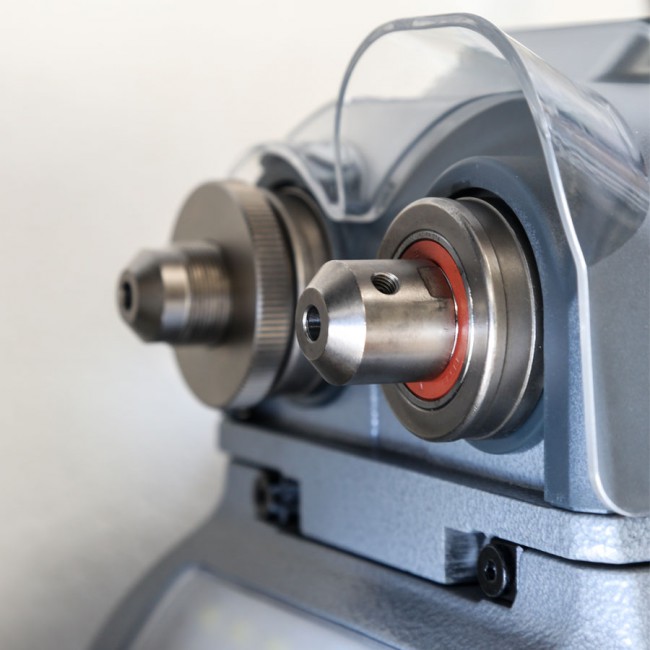

3. Installing and Removing Probe/Cutter

1) The left one is a tracer and the right one is a cutter. Put the tracer and cutter into the hole and to the top limit position. Then use a 2.5mm Allen wrench to turn the lock screw clockwise respectively till the tracer and cutter are both tightened.

NOTE: When using a 1.5mm cutter and 2.5mm cutter, tracer and cutter must select the top with the same diameter for processing.

2) Insert the wrench into the hole, turn the lock screw counterclockwise, and then remove the trace and cutter.

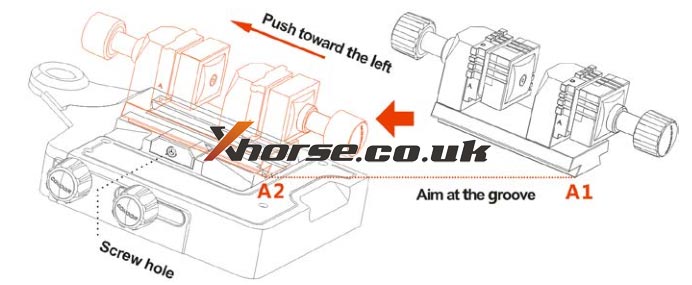

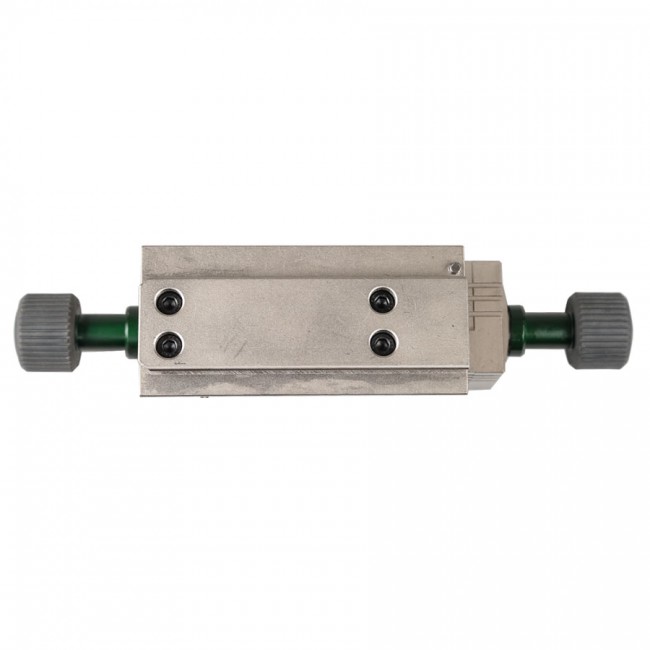

4. Clamp Installation

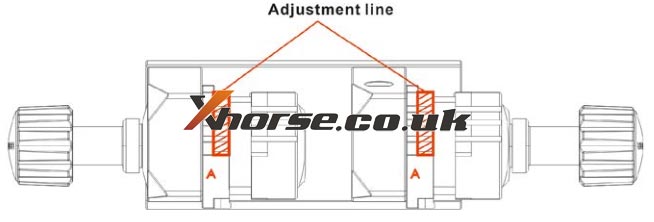

Aim the bump (A1: underneath the clamp) at the cutting bench's groove (A2), push toward the left until A1 and A2 (shown above) are fully overlapped. Then use a 4mm Allen wrench to tighten the screw.

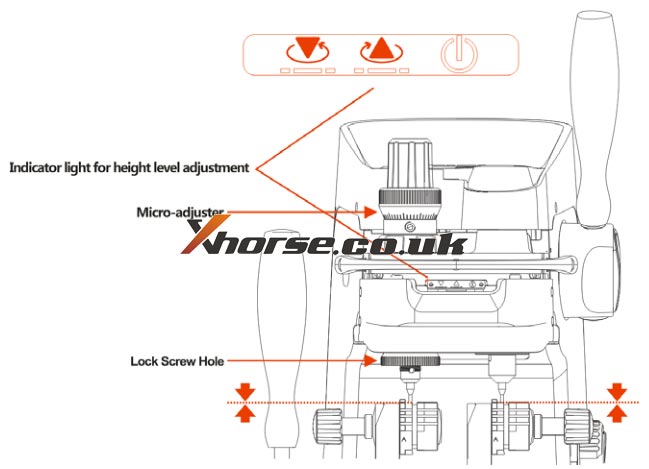

5. Probe/Cutter Height Level Adjustment

1) When the installation finished, push the main handle. If the tracer is higher than the cutter, the indicator light on the left will turn on.

2) If the tracer is lower than the cutter, the indicator light on the right will turn on.

3) According to the signal of the indicator light, rotate the Micro-adjuster until the tracer and cutter's tops have both touched the clamp. In other words, they are at the same height. Then two indicator lights will on, adjustment finished.

NOTE: During the height level adjustment, the main clamp and sub-clamp must on the same side.

6. Rotation Speed Adjustment

Rotation adjustment knob locates at the right side of the machine. There are two gears to control the rotating speed of motor.

1) When the adjuster is at the neutral gear, the motor stays at "Turnoff" mode; when it points to "OFF", the light will be on, means the machine is ready to work

2) When the adjuster points to "1", the motor rotates at a low speed, about 6000rpm; when it points to "2", the rotation speed is higher, about 8000rpm.

CONDOR XC002 Detailed Pic:

Condor Key Cutting Machine Comparison:

Condor XC-002 Package Including:

1pc x Main unit

1pc x Multi-functional clamp

1pc x Power cord (1.5m)

1pc x Brush

1pc x Main handle

1pc x Sub-handle

1pc x 2.5mm cutter

1pc x 1.5mm cutter

1pc x Tracer

1pc x 2.5mm Allen wrench

1pc x 4mm Allen wrench

2pcs x Key alignment block blade

1pc x Product packaging checklist

1pc x User manual

Contact us to get a good price:

Email: Sales01@Xhorse.co.uk

Skype: service@xhorse.co.uk

WhatsApp: +86 17308368390

Video

Introduction to Xhorse Condor XC 002 Mechanical Key Cutting Machine

Tech Support

Xhorse Condor XC-MINI,Condor XC-002,XC007 Key Cutting Comparison

Condor key cutting machine Specification Comparsion:

| Key cutting machine |

Condor XC-007

|

Condor XC-MINI

|

Condor XC-002

|

| Input Voltage | AC110V/220V | 90V–264VAC | 220VAC |

| Input Frequency | 47~63Hz | 47~63Hz | 50Hz |

| Consume | 220W | 200W | 200W |

| Packing Dimensions | L460*W 520*H 620mm | L450*W450*H350mm | L595*W550*H375mm |

| Machine Dimensions | L336*W 407*H490mm | L265*W362*H301mm | L298*W445*H525mm |

| Display | 800*480 | 1024*600 | |

| Spindle Speeds | 12,000 rpm | 9000rpm | 8000-10000rpm |

| USB | USB2.0 | USB2.0 | |

| Working Temperature | 0~50℃ | 0~50℃ | 0~50℃ |

| Humidity | 10~90% | 10~90% | 10~90% |

| Net Weight | 31Kg | 18Kg | 23Kg |

| Gross Weight | 35Kg | 22.9Kg | 28Kg |

2.Xhorse iKeycutter Condor machines Differences::

Condor XC MINI master is the mini version of Condor XC-007 machine,can replace XC-007.And both of them are automatic key cutting tool.

But the new Condor XC-002 is a manual/mechanical key cutting machine.

XC MINI has no limitation in applied voltage, while XC-007 needs setting, use with 220V voltage

Optional parts & accessories

Customers who viewed this item also viewed

![IKeycutter CONDOR XC-MINI Master Series Automatic Key Cutting Machine Update Online DHL Free [Promo]](http://www.Xhorse.co.uk/upload/pro/ikeycutter-condor-xc-mini-1801.jpg)